Rug Making Process from Design to Finishing

Design work ranges from painting to photography to digital which is useful flexibility in collaborating with commissioners.

I have yarn colours already in stock but there’s always more needed to achieve the effect I want which I source from a few different suppliers. There is no end to colour and tonality in the spectrum. Photo by Euan Adamson

Rug is drawn up to scale and allows organic changes and improvements to be made in the process. I have to work with the reverse image as a rug is tufted back to front.

The cut ends of the yarn reflect light differently from the length, which changes the tone and colour, so I use the cut ends to check what looks right together, often combining two or three colours to achieve the look I want. I spend a long time winding little poms to check colours and combinations. Photo by Euan Adamson

I thread my tufting gun up and away I go! Its not just plain sail tufting though, as I probably spend as much time changing colours, checking colours, checking tonality, checking design, checking pile quality. Photo by Euan Adamson

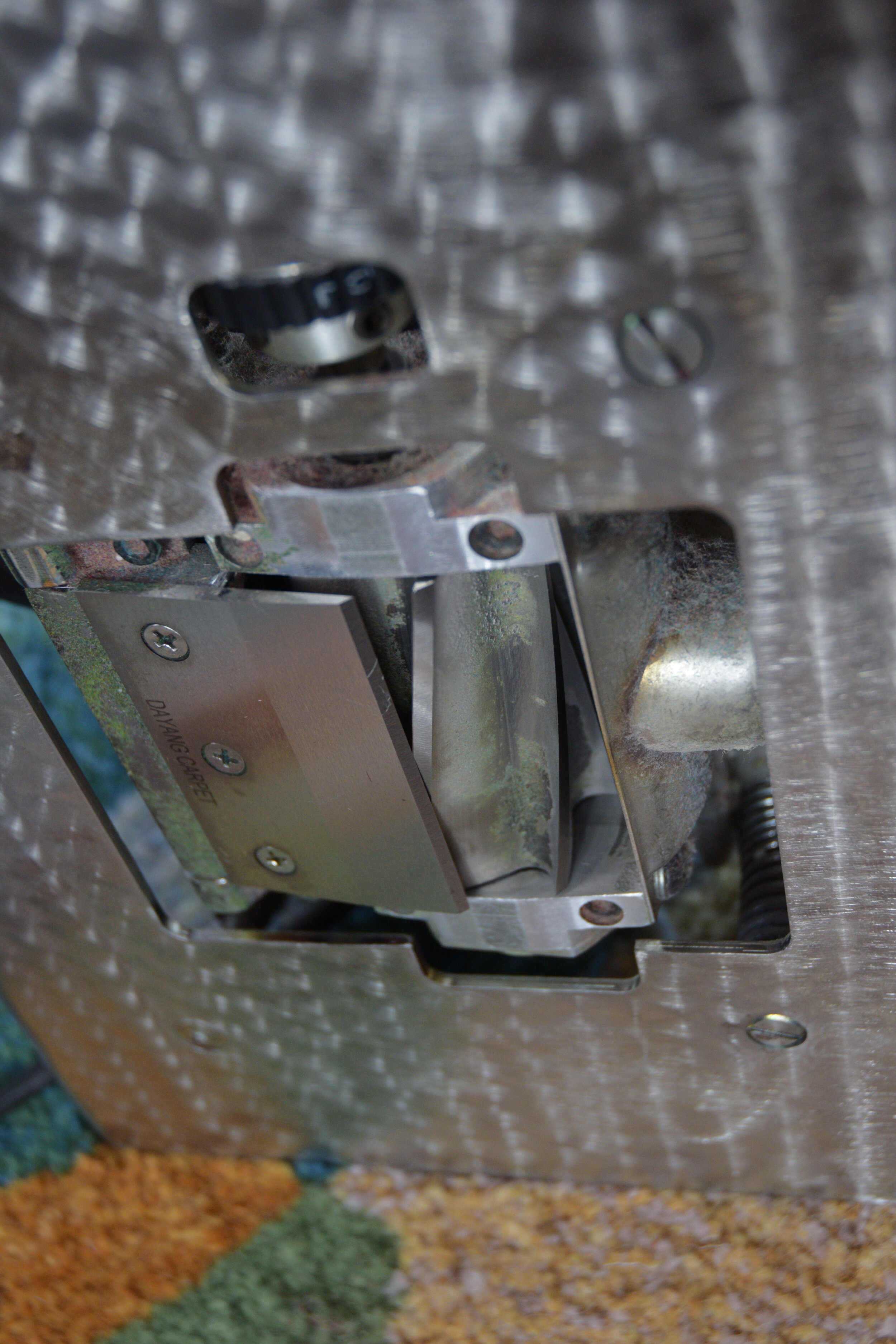

The mechanism of the gun extends sharp scissors and closes them to cut the yarn at pile height please see the video below. Photo by Euan Adamson

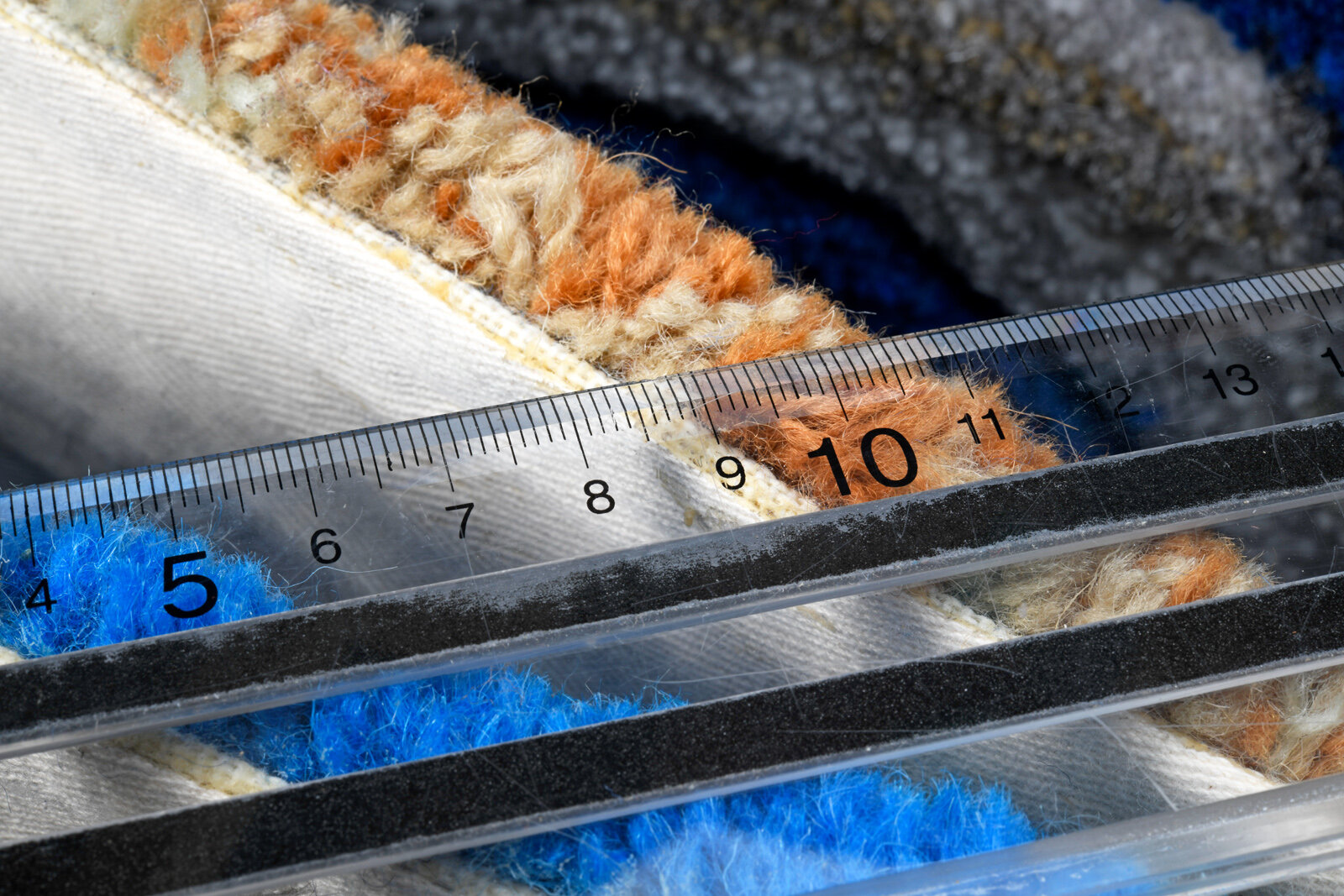

To achieve the level of detail I do on some rugs, I generally tuft a 12mm to 15mm pile height tufting in as many ends as feels right which depends on the gauge and quality of yarn; on average 100 to 200 ends per square cm, so the ends support each other, stay upright and resiliently springy. Photo by Euan Adamson

Video by Euan Adamson

When finished tufting i cut the rug down and fix a sturdy natural cotton drill fabric onto the back using natural latex. I use a matching cotton binding to finish off the edge.

I use a natural cotton binding to finish off the edges

Then I flip the rug over and shear the pile which really brings up the definition of the design. Carving relief into some designs can create greater definition and textural artful effect. The more even the surface of your rug the easier it is to maintain.

The shearing machine has a blade on the underside which whizzes round trimming small, careful amounts of the pile height at a time. Photo by Euan Adamson

I use other tools such as hoovers to massage any loose ends out of the pile, so the shearer can catch them next time round, and scissors and sheep shearers to carefully finish edges.

Rugs sit at about 15 to 18mm high off the floor when completely finished and because the pile springs over at edges the cotton backing cannot be seen when on the floor. Photo by Euan Adamson